Applications:

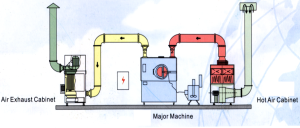

The efficient coating machine consists of major machine, slurry spraying system, hot-air cabinet, exhaust cabinet, feed and discharge device, and computer programming control system.

It can be widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc. In such fields as of pharmaceutical, food and biological products etc. And it has such characteristics as good appearance in design, high efficiency, low energy consumption and small floor area, etc.

Basic working principle:

The tablets make complicated and constant track movement with easy and smooth turn frequent exchanging in a clean and closed drum of the film coating machine. The coating mixed round in the mixing drum are sprayed on tablets through the spray gun at the inlet unaction of the peristaltic pump. Meanwhile under the action of air exhaust and negative pressure 100,000 clean hot air supplied by the air exhaust cabinet is exhausted from the fan at the sieve meshes through tablets. So these coating mediums on the surface of tablets get dry forming a coat of firm, fine and smooth film. The whole process is finished under the control of PLC.

Details as follows:

1. Main Machine

During the film coating process in the major machine, it shows such features dust fly off, no syrup splash, operation condition improvement, little cross contamination to tablets, simple coating process, coating time shortening as well as high production efficiency etc.

There adopted a new & mini-type computer and a touch screen on which temperature and negative pressure control system are displayed with such functions programmability, automatic adjusting such a majority of process parameters flow, negative pressure, intake, exhaust, temperature, rotational velocity the compile of SOP digitizing, making no difference between various batches products with the same technical parameter. It adds data storage and printing functions with more than 14 program film coating (Option item), which are modified at any time in the run. The printing device finished as to the customers' requirement so that the process parameters process flow of each batch of production can be accurately recorded and domestic advanced level. The users may write batch numbers and the codes products on their needs.

2. Hot Air Cabinet

The hot air cabinet is made up of cabinet body, frequency conversion speed adjustment, centrifugal fan, filtration system, heat exchanger.

The cabinet can directly take in outdoor air, which can meet 100,000 level cleanness requirements through primary, medium and high level filtration with 95% dust powder with dia. more than 5um purified. The purified air, heated to 80℃ by the heat exchanger, enters the coating drum.

3. Air Exhaust Cabinet

The exhaust cabinet consists of cabinet body, explosion-proof centrifugal fan, dust-removing filtration system. The cabinet is used to keep the coating drum operating chamber under negative pressure, dust-removing and filtration for the exhaust air.

The exhaust outlet is equipped with a reflux-proof device. Close the exhaust cutlet before stop the machine to prevent the air in the exhaust cabinet from reflux. It is equipped with a dust abatement & filtration by vibration. So the vibration and dust are insulated, the dust is presented from fly off and the dust abatement is automatically separated, which makes cleaning easy.

4. Thermal Stirring Drum

Thermal stirring drum adopts electric heating type. It is equipped with pneumatic stirrer which is driven by compressed air, stable rotating speed and stepless speed regulating, medium can be stirred homogeneous. It can be controlled automatically at normal temperature to 80℃, easy-operating, safe and reliable. All parts are made of stainless steel, inside and outside is mirror polished.

5. Peristaltic Pump

- Technical parameters:

- Flow: 480L / H --- 14,000L / H

- Material viscosity range: 0.2CP-500,000CP

- The highest pressure of outlet: 0.8MPA

- Product temperature: -30°C ---- 150°C

Performance and Characteristics:

- All operations can be finished through pushing the touch key on the computer-controlled panel. The operational panel is a full-sealed slight touch film interface. The main machine as reliable and stable performance.

- The streamline guiding-type mixer drives tablets to make easy and smooth rotation without fragment and chipped edge, which improves the quality of finished products.

- The coating boiler equipped in the high pressure spray gun, which can rotate 180℃, there set a cleaning sprayer at the air exhaust exit and hot air mouth, which can be rotated in automatic and full direction,without dead corner more convenient to clean.(Option)

- Select the imported spray gun. It's convenient to operate and easy to master and flexible controlled technological requirement. The spray gun head requirement must keep in the range of 0.29 Mpa to 0.39 Mpa. Angle and sector can be adjustable, uniform density and particle in spray pressure and 0.4-0.5Mpa in atomization pressure that avoid the dropping leakage and blockage phenomenon of size, uniform atomization and large spray area, practical to adjust flow, free leakage and blockage, angle and sector.

- Film coating machine contains the mechanical device of cauldron wrapping little material can coat at least 30kg plain pills in 150 type coating machine, regulate through it inherent machinery, make a small amount of medium coat in cauldron and will not cause the wasted of dressing and greatly improve the scope of appliance.

Main Technical Parameters:

| Item | BG-150E | BG-260E | BG-400E | BG-600E |

| Capacity | 150L | 260L | 400L | 600L |

| Diameter of coating drum | φ1200mm | φ1360mm | φ1580mm | φ1580mm |

| Diameter of feeder | φ475mm | φ475mm | φ475mm | φ475mm |

| Rotary speed of drum (R/min) | 0-16r.p.m | 0-16r.p.m | 0-13r.p.m | 0-12r.p.m |

| Power of Main machine | 2.2kw | 2.2kw | 3kw | 5.5kw |

| Power of air exhaust cabinet motor | 5.5kw | 5.5kw | 7.5kw | 11kw |

| Flux of air exhaust | 7419 m3/h | 7419 m3/h | 10000 m3/h | 15450 m3/h |

| Power of hot air cabinet motor | 1.5KW | 2.2KW | 2.2KW | 5.5KW |

| Flux of hot air | 2356m3/h | 3517m3/h | 3517m3/h | 7419m3/h |

| Hot air adjustment scope | ~800C | ~800C | ~800C | ~800C |

| Level of hot air purified | 100,000 level | 100,000 level | 100,000 level | 100,000 level |

| Power of peristaltic pump motor | 0.18KW | 0.55KW | 0.55KW | 0.55KW |

| Electricity Power sources | 36KW | 48KW | 50KW | 69KW |

Reviews

There are no reviews yet.