- Overview

BG H-type efficient coating machine is an experimental equipment for special use widely applied in Chinese and western tablets, pills and the like for carrying out water phase and organic film coating. This equipment is manufactured in strict accordance with the requirements of pharmaceuticals industry association ‘‘GMP’’, and all shells, coating rollers, heat fans, exhaust fans, spraying devices, and all components in contact with drugs are produced by stainless steel materials. The whole operation process is controlled by a PLC programmable system, comprising a manual operation control and automatic operation control. The control system is controlled by the PLC programmable system, the control parameters are displayed on the touch frequency. The whole coating operations are carried out under a closed state and dust flying and coating solution spattering free, it is a novel and efficient coating device characterized in efficiency, reliability, clean, energy-saving, less covering areas, easy operation, and in accordance with GMP requirements.

- Features

- Provided with a controllable negative pressure function: the negative pressure testing point is added to a coating machine, in accordance with the technological requirements (e.g. the negative pressure value is 10Pa), the electronic control system can be operated by operators to control the speed of the exhaust fan, changing the wind speed and capacity thereof, achieving the purpose of controlling the negative pressure in the pot.

- Provided with a controllable wind-speed system for hot wind: in accordance with the technological requirements, operators can operate the electronic control system for controlling the rotate speed of the air heater, changing the air-supplying capacity and wind speed thereof, and achieving the technological requirements.

- Temperature value display and control: a temperature sensor is configured in the air inlet and outlet of the coating drum, the temperature signal automatically controls the heat exchanger after inputting to PLC and compared with the set value (at 80 degrees centigrade), thus to control the coating temperature values, the control accuracy is up to plus or minus 2 degrees centigrade.

- An import spray gun is selected, the operation thereof is convenient and easy to master, and the process requirement is controlled flexibly, the spearhead cannot work until it is provided with the 0.29 to 0.39MPa of shot pressure and 0.4 to 0.5MPa of atomization pressure, thus to prevent the dripping, leaking and blocking, and the flow, angle and fanning are adjustable, which is characterized in uniform atomization, large spray surface, non-dripping, and auxiliary materials saving.

- Provided with constant printing function: technological parameters related to the production process of automatic real-time record are designed, capable of printing in accordance with requirements, avoiding the error of manual records, and ensuring the truth and reliability of the original records.

- A roller replaceable function is designed: 3replaceable coating rollers are designed, which facilitates the trial-produce for small batch of drugs and the exploration of the coating process, and the roller can be replaced quickly and conveniently.

- Host and hot-wind mechanism are designed in all-in-one, reducing the floor space.

- Working principle

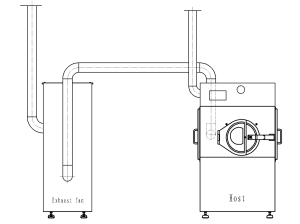

BG-H efficient-intelligent coating machine is mainly composed of a host, spray system, hot air system, ventilation cabinet, PLC programmable system, and electrical cabinet. (Shown in figure 1)

Figure 1

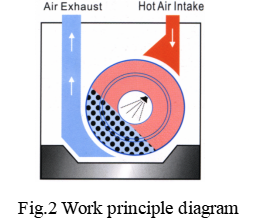

The basic principle of the BG-H type efficient coating machine: the bottom of the coating pot is produced by sieve trays and the coated sheet core performs a continuous & complex trajectory in the roller of the coating machine. During the motor process, the PLC programmable system is responsible for control, the medium is sprayed in mist on the surface of the sheet core via a pump and spray gun automatically according to the process sequence and the selected process parameters, at the same time, the sheet bed is penetrated by the hot air system via a level of 100,000 filtered clean hot air, extracted from the bottom of the roller via an exhaust fan, discharged after dust removal, thus to making the sheet core shaping the solid and smooth surface film. (Shown in figure 2)

- Technical parameters

| Model | BG-5H | BG-20H | BG-80H | |||||

| Diameter and capacity of coating roller | Ф480 | 5 kg | Φ520 | 5 kg | Φ680 | 10kg | ||

| Ф380 | 3 kg | Φ580 | 10 kg | Φ750 | 40 kg | |||

| Ф300 | 1 kg | Φ680 | 20 kg | Φ930 | 80 kg | |||

| Speed adjustable range of coating roller (rmp) | 0-30 | 0-30 | 0-30 | |||||

| Coating roller motor power(kW) 9 | 0.37 | 0.75 | 1.5 | |||||

| Air heater motor power(kW) | 0.25 | 0.75 | 1.1 | |||||

| Air heater flow m3/h | 504 | 1200 | 1685 | |||||

| Tempering range of hot blast (degrees centigrade) | Room temperature: 90 degrees centigrade | |||||||

| Exhaust fan motor power(kW) | 1.1 | 2.2 | 3 | |||||

| Exhaust fan flow m3/h | 2500 | 3517 | 5268 | |||||

| Peristaltic pump power(kW) | 0.03 | 0.05 | 0.55 | |||||

| Outline dimension (mm) | 1250×900×1700 | 1050×960×1800 | 1300x1315×2000 | |||||

| Weight (Kg) | 1583 | 625 | 800 | |||||

| Dimension of hot-air fan (mm) | / | 900×800×1935 | ||||||

| Weight of hot-air fan (Kg) | / | 450 | ||||||

| Exhaust size(mm) | / | 650×600×1800 | 900×820×1850 | |||||

| Exhaust weight (Kg) | / | 235 | 550 | |||||

| External conditions | Clean air | Pressure Mpa | ≥0.4 | ≥0.4 | ≥0.4 | |||

| Air consumption m3/min | 0.6 | 0.6 | 0.6 | |||||

| Water source | Pressure Mpa | ≥0.15 Not less than 0.15 | ≥0.15 Not less than 0.15 | ≥0.15 Not less than 0.15 | ||||

| Electric heating | Power source kW | Three-phase five line 10 | Three-phase five line 14 | Three-phase five line 36 | ||||

Reviews

There are no reviews yet.