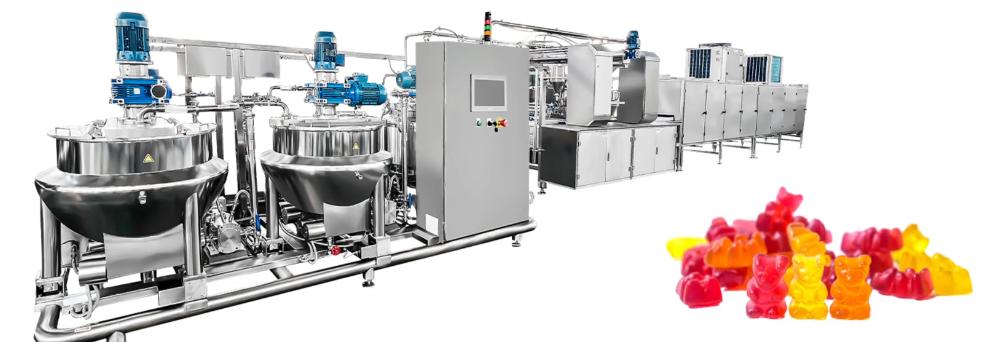

Automatic Gummy Candy Production Line

- Automatic depositing syrup into molds, followed by automatic cooling and demoulding.

- Two different types of CFA systems are available for adding colors and scents automatically, or adding acidic vitamins and other powders or liquids.

- PLC and touch screen provide the latest technology for programming all controls and operations.

- Efficient work can gain more benefits, save manpower and prolong machine life.

Introduction:

The Automatic Gummy Production Equipment is a stand-alone system capable of full production duties, including the whole process of cooking, depositing, cooling and coating. With speeds up to 80-600 kgs of gummies per hour, it is perfect for small to medium scale production runs. This equipment can produce gummies in one or two colors.

Cooking system——Depositing machine——Cooling tunnel——Sugar coating

Features:

- PLC control system

- LED touch panel for easy operating

- Special designed de-moulding device

- Different shape be made via change-over of moulds

- In-line injection, dosing & pre-mixing for proportional additionof liquid

- Dosing pump for automatic injection of colors, flavours andacids

- Available for one colour, two colours jelly candies

- Sanitary construction

- Deposited hard candies can be produced on same line by changing moulds

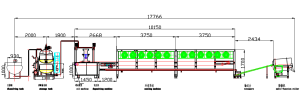

Main parameter:

| Model | SGD-80 | SGD-150 | SGD-300 | SGD-600 |

| Candy weight | 1-10g | 1-10g | 1-10g | 1-10g |

| Capacity | 80kg/h | 150kg/h | 300kg/h | 600kg/h |

| Output | 26000-30000pcs/h | 30000-36000pcs/h | 70000-86000pcs/h | 140000-18000pcs/h |

| Depositing Speed | 25~55min | 25~55min | 25~55min | 25~55min |

| Electric power needed | 80KW | 120KW | 169KW | 200KW |

| Total length | 12M | 18M | 18M | 22M |

| Weight of Machine | 2000kg | 3000kg | 8500kg | 12000kg |

- Cooking system

It is an automatic system for ingredients to dissolve and mix. After sugar, glucose and other raw materials are mixed with syrup in the vessel, the mixed ingredients will be transferred to the holding tank for the next step of production. The process of cooking is controlled by a separate control cabinet.

It is an automatic system for ingredients to dissolve and mix. After sugar, glucose and other raw materials are mixed with syrup in the vessel, the mixed ingredients will be transferred to the holding tank for the next step of production. The process of cooking is controlled by a separate control cabinet.

- Depositing machine

The depositing machine is developed with advanced production technology. Recent improvements in research and development have greatly enhanced performance, increased automation, and extended service life.

It is used for the continuous production of various shapes of candies. It is an ideal equipment for the production of high-grade candies, which can produce single-color candy, double-color candy, and center-filled candy.

- Cooling tunnel

The device is air-cooled and comes with a brush and air blowing function to aid in mold release.

The defrosting and dehumidification settings can be set according to the needs. If the temperature needs to be controlled below 15 degrees Celsius, the demoulding will be smoother. Open the conveyor belt in advance before making candy.

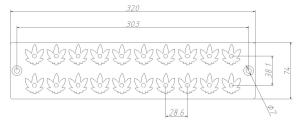

- Mould (shape can be customized)

Placed candy molds on a conveyor belt for depositing.

- SUGAR COATER (easy clean type)

Features

- High degree of hygiene and sanitation

- Fine steam regulation and application to suit various jelly shapes and sizes

- Optimum coating to give quality appearance to products

- Easy drum cleaning

- The sugar is dry and free owing

- Economical sugar usage

- Low maintenance

- All made by SUS304

- Size: 2000mm*1600mm*1700mm

- Weight: 360KG

Reviews

There are no reviews yet.